Liebherr is ready to strengthen the reputation of the R 9100/R 9150 excavators when its B versions of the machines arrive at Australian mines this year.

As the R 9100 has proved to be a worthy successor to the R 984 C excavators over the past seven years, Liebherr is convinced the B versions will add further benefits.

Liebherr delivered widespread improvements on the R 984 C with the R 9100 and R 9150, and set similar expectations during development of the new models.

The original versions have, however, provided a strong foundation for Liebherr to build on.

Liebherr launched the R 9100 in 2010 and the R 9150 two years later. Since 2012, the OEM has sold machines for operation in 21 countries over six continents.

The excavators have operated for more than one million hours at the mines, with a third of the machines recording more than 15,000 hours each.

They are used across operations for numerous commodities, including gold, coal, iron ore, copper, nickel and manganese.

Australian miners and contractors are amongst the users of the machines, including Blue Cap Mining, which operates two R 9150 excavators at gold sites in Western Australia and Queensland.

Blue Cap general manager Paul Allen says the R 9150 has many notable qualities that have made it suitable for the small hard rock operations where they are in use.

“We have seen both excavators perform well at different sites with different challenges,” Allen tells Australian Mining.

“Part of the reason we went for the 9150 was the specification and capacity of the machine, its hydraulic system and the additional power you are pulling in that unit – it has 565kW.”

Blue Cap pairs the excavators with haul trucks in the 100-tonne class, a match that been a strong fit for the designs of the pits at the gold sites.

Another key factor that helped the R 9150 stand out for Blue Cap was the technology Liebherr included on the machines, Allen continues.

“It was (at the time) more about some of the newer technology that Liebherr embedded around productivity and fuel efficiency,” he says.

“We are seeing around 15-20 per cent more efficiency out of this digger compared to some competition.”

With the success of Blue Cap’s R 9150 excavators, Allen has taken a keen interest in the updates incorporated on Liebherr’s updated models.

The B-version excavators were launched in January and the first machine in Australia will be received this month.

Liebherr senior product manager – mining excavators George Barturen backs the new excavators to drive productivity at mining operations, whatever the environment.

“Such systems are robustly designed and will be very well suited to the Australian mining environment from our extensive experience over the last five decades,” Barturen says.

“The B series machines, as was the R 9100 are suited to all mining and quarrying operators as the machine brings a competitive advantage regardless of the mined commodity with a reduced cost per tonne.”

Stepping up operations

Liebherr’s updated hydraulic excavators have been developed to provide a step forward in performance and reliability, while lowering the cost per tonne.

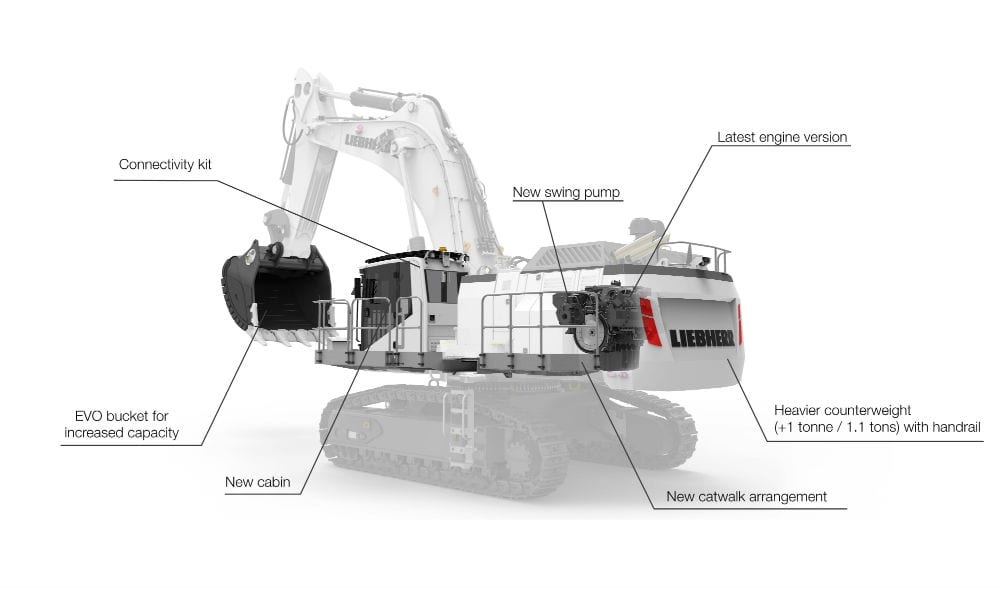

Both models have received upgrades across the machine, including the latest generation of Liebherr’s D9512 engine, which offers an increased lifetime target of 15,000 hours, and other features that support maintenance efficiency.

The B versions include the exclusive EVO Bucket Solution, maximising loading capacity and ensuring optimal penetration efficiency.

With contoured sidewalls and augmented depth, the EVO Bucket has a 7.5m3 capacity on the R 9100 B and 8.8m3 and 9.6m3 on the R 9150 B, the latter being available on machines configured with a shorter boom.

The buckets match the excavators with the Liebherr T 236 truck, as well as other articulated and rigid trucks in the 50–100-tonne class.

Liebherr has positioned the R 9150 B directly between the 100-tonne and 200-tonne class machines with its bucket capacities. The R 9150 B begins to challenge the productivity of larger machines in the 200-tonne class with 12m3 buckets.

Barturen says incorporating the patented EVO Bucket design to the new machines is the most significant advance that increases productivity.

“This has brought about an increase in bucket payload with a reduction in bucket weight, whilst maintaining the same fast cycle time,” Barturen says.

“Additionally, the EVO Bucket for backhoe machines Liebherr is introducing several patented innovations together with machine functional control systems to provide the operator with semi-automatic functions increasing the overall efficiency and productivity of both machines.”

Barturen, a Liebherr employee since 1991, has worked closely with the company’s mining excavator team on the development of the B versions.

Alongside fellow Liebherr product manager Michel Runser, Barturen has guided the excavators through their final stages of development before launch.

“The main drivers in the development process were to improve the machine as a whole, enhancing machine safety, improving reliability and productivity KPIs and introduce operator comfort options, both active and passive.” Barturen says.

“The Australian mining industry drives continuous improvement of the machines through the different standards, guidelines and mining industry associations.

“Additionally, Liebherr has an internal global reporting system, which brings feedback directly into the factory from the field, speeding up the implementation and introduction of suggested improvements to suit the market, which is continuously driving improvement.”

Updated Liebherr engine

This series of Liebherr excavator was the first to introduce the OEM’s own diesel engines, a milestone reflected in the B versions. The R 9100 B and R 9150 B are equipped with Liebherr’s latest D9512 V12 diesel engine, which exists in Tier 2 and USA/EPA Tier 4 final version.

Liebherr Australia executive general manager, customer service, Tony Johnstone says the company’s service team has updated its skillset to support the new engine since its introduction.

Johnstone believes this has led to a new approach for the team, which has previously serviced and maintained engines from other OEMs.

“For us the challenge has been the development of our service technicians to be ready to work on the machines, understand the systems and be able to provide the best services that are required for customers,” Johnstone says.

“We’ve also had the challenge of upskilling our technical trainers so that we could train all of our service technicians in the Liebherr engine.”

Liebherr’s Australian-based technicians completed training on the engines in the company’s Switzerland engine factory certified training centre, with focus on control systems, maintenance and diagnostics.

In addition, customer training will be provided by Liebherr certified trainers at the new technical training centre at the Para Hills West facility in Adelaide.

The company has also ensured it has widespread availability of the unique service and maintenance parts for the engine.

“We had to stock appropriately for parts and for the future which we are working on now; we are enabling our remanufacturing centre to rebuild and run the D95 series engine,” Johnstone says.

“It has been a ground up approach because it was the first Liebherr engine in a Liebherr mining excavator.”

Liebherr’s preparation for the change of engine has the services team well placed to support the B versions once they arrive in Australia.

The R 9150 B will also be available in electric drive.

Comfort and safety first

The B-version machines feature an upper structure that is accessible via a robust fixed ladder or 45-degree access stair in option. It integrates one large central platform equipped with slip resistant surfaces.

Liebherr has designed the new arrangement with wide catwalks to facilitate maintenance and to ensure comfort during operations.

“Included in the upgrade was the integration of hard safety systems – an improved catwalk on the left side of the machine, together with a handrail installation on the counterweight for added safety during machine and engine maintenance tasks,” Barturen says.

“Integration of HEPA filtration of the operator cabin is available should the requirement be needed.”

The cab, updated with improved ergonomics and operator attenuation, provides the ideal working platform and optimal comfort for operators.

Liebherr’s resiliently mounted cabin on ISO mounts reduces vibration, while a new cabin interior liner provides a two decibel decrease in noise levels in the cabin for the operator.

Technology advances

Liebherr has shown its awareness of modern connectivity needs, equipping the B version machines with GSM data transmission, together with the ability to transmit on customer site networks to provide operating parameters, error codes and machine faults.

Machine end users can access the data through the Liebherr Mining Data (LMD) platform, and generate custom reports to track and analyse machine data.

Barturen says the excavator product team focused on Liebherr’s six pillars of mining: safety and environment, productivity, efficiency, reliability, customer service, safety, and environment when enhancing the machines with technology.

“Improvements to the machines’ operating systems provides enhanced machine operational efficiency. Together with the integration of machine data management and analytics, the B series will enable customers to increase the effective utilisation of the machine in lowering the cost per tonne,” Barturen says.

“Customer service is enhanced by on board systems for the management of the machines’ maintenance and reliability interfacing with the Liebherr developed Troubleshoot Advisor.”

The data collected by the connectivity kit is recorded in a worldwide database for processing and assessment by Liebherr.